Product Category

Full automatic PET bottle blow moulding machine

Product Description:

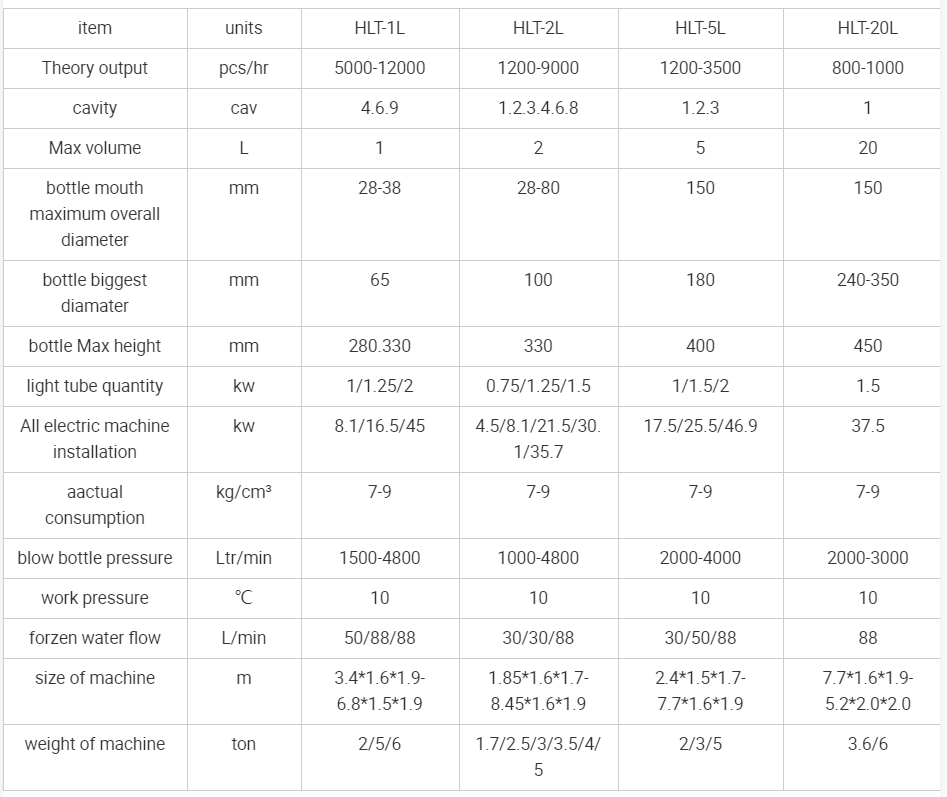

Huili Machinery's energy-saving fully automatic PET bottle blow molding machine is a high-performance intelligent device specially designed for large-scale production of multi-specification PET plastic containers. It includes four core models: HLT-1L, HLT-2L, HLT-5L, and HLT-20L, with volumes ranging from 1L to 20L, and can flexibly adapt to different production capacities and packaging requirements. The equipment integrates international advanced manufacturing

technologies, adopting core components from renowned brands such as Delta from Taiwan, Festo from Germany, and Izumi from Japan. It is equipped with a stable infrared heating system and high-precision mold closing technology, achieving fully automated and pollution-free production from preforms to finished bottles. Its energy-saving design significantly reduces the consumption of electricity, gas and water. The finished bottles feature high transparency and dimensional accuracy. Coupled with one-stop turnkey engineering services, it provides efficient and reliable packaging production solutions for industries such as food and beverage, daily chemicals, and pharmaceuticals and chemicals.

|

Core Advantages:

Intelligent and efficient, easy to operate: Equipped with a touch screen control system, the real-time operation status of the equipment is visually presented, and it can be operated without complex training. The multi-cavity design (1-9 cavities) is available, with a theoretical output of up to 12,000 per hour, efficiently matching the demands of large-scale production.

Outstanding quality, stable and reliable: A stable infrared heating system is adopted to ensure uniform heating of the preform, and high-precision blow molding and clamping technology precisely controls the molding process. The finished bottles have high transparency and small dimensional errors. The core components are all selected from internationally renowned brands, resulting in a low failure rate during equipment operation and a long service life.

Clean production, strong compliance: The enclosed production area effectively isolates external contamination, and the high-quality self-lubricating system prevents lubricating oil leakage from affecting materials. It fully complies with the clean production standards of the food, pharmaceutical and other industries, ensuring product safety.

Energy conservation and consumption reduction, with controllable costs: The optimized power system design significantly reduces the consumption of electricity, gas and water. Combined with modular energy consumption configuration, it can be flexibly adjusted according to production needs. Long-term use can significantly lower production costs.

Comprehensive service, worry-free: We offer a one-stop service covering factory layout planning, equipment installation and commissioning, operator training, and lifetime after-sales support. Free maintenance is provided within the one-year warranty period, and lifetime technical support is offered to completely eliminate any concerns about production.

Machine Features:

Multi-specification compatibility: Four major models cover volumes ranging from 1L to 20L, bottle mouth specifications from 28mm to 150mm, maximum bottle diameter of 350mm, and maximum height of 450mm, which can meet the production requirements of PET bottles of different shapes and sizes.

The core configuration is high-end: The PLC is from Delta of Taiwan, the cylinders are from Airtac of Taiwan or Festo of Germany, the valves are from Festo of Germany, and the relays are from Izumi of Japan. International first-line components ensure the stable operation of the equipment.

Stable and controllable working conditions: The working air pressure is uniformly set at 7-9kg/cm³, the chilled water temperature remains constant at 10℃, and the bottle blowing air pressure is adapted to 1000-4800L/min according to the model, ensuring a stable and consistent molding process.

Reasonable structural design: The equipment is compact in size (1.85m×1.6m×1.7m to 7.7m×2.0m×2.0m), weighing 1.7 tons to 6 tons, suitable for different workshop layouts, and supports visual detection. It is easy to maintain and has low noise.

Application Scope

This equipment is applicable to a wide range of industries and can produce various PET material containers, covering the needs of multiple scenarios

Food and beverage industry: 1L/2L carbonated beverage bottles, mineral water bottles, juice bottles, 5L/20L large-capacity drinking water buckets, edible oil bottles, etc.

Daily chemical and beauty industry: cosmetic bottles, skin care product bottles, shampoo packaging bottles, etc. with 28-80mm bottle mouths;

Pharmaceutical and chemical industry: reagent bottles, pesticide bottles, chemical raw material packaging bottles, etc.

Household and daily-use industry: wide-mouth storage tanks, large-capacity storage bottles, various daily-use packaging bottles, etc., fully meeting the customized production needs of different industries.

photo for blow mold (see below)

photo for final bottle (see below)

photo for preform (see below)

injection moulding machine(to product PET preform and lid)

Transportation and Packaging

Packaging standard: The main unit is sealed with wooden pallets and plastic film, effectively preventing dust and moisture. Auxiliary equipment and spare parts shall be uniformly packed in solid wooden cases to ensure they are not damaged during transportation.

Transportation regulations: When loading into containers, strictly follow the principle of weight balance for placement. All packaging is reinforced with fixed devices to prevent damage to precision components due to shaking and collision during transportation. After shipment, we will promptly provide complete photos of the transportation site for customers to keep abreast of the status of the goods in real time.

Installation Tips: Sufficient space for operation and maintenance should be reserved during equipment installation. Match the corresponding power supply, air pressure and chilled water supply according to different models (for specific parameters, please refer to the specification table). It is recommended that professional technicians install and debug on-site.

Maintenance and Upkeep

Daily maintenance: Clean the surface of the equipment and the enclosed production area every day, and remove dust and debris. Check the working condition of the infrared heating tube and replace the aged or damaged parts in time. Observe whether the gas and water lines are unobstructed and check for any leakage.

Regular maintenance: Check the self-lubrication system weekly, replenish lubricating oil and ensure the oil passage is unobstructed to avoid dry grinding of components. Clean the impurities in the gas filter and replace the coolant in the chilled water system every month to prevent pipeline blockage. Check every quarter whether the circuit connection is firm and clean the dust inside the control cabinet to avoid short-circuit faults.

Long-term maintenance: Conduct a comprehensive inspection every six months, with a focus on checking the operational status of core components such as the clamping mechanism, PLC control system, and cylinders. Operate strictly in accordance with the maintenance manual provided by the manufacturer. Non-professionals are prohibited from disassembling core components without authorization to ensure the stable operation of the equipment.

Reference for User Reviews

This energy-saving PET bottle blow molding machine has won the recognition of many enterprises in the food and beverage, daily chemical, and chemical industries with its multi-specification compatibility, high efficiency and energy saving, as well as stable quality. User feedback indicates that the equipment model selection is rich, ranging from 1L small bottles to 20L large barrels, perfectly matching the diversified packaging needs. The touch screen operation is simple and intuitive, and workers can quickly get started. The high-capacity design has significantly improved production efficiency. The finished bottle has high transparency and precise dimensions, fully meeting the appearance and sealing requirements of product packaging. The closed production design effectively avoids pollution problems and smoothly passes industry compliance tests. Meanwhile, the low energy consumption feature significantly reduces long-term production costs. Coupled with the professional installation training and lifetime after-sales service provided by the manufacturer, the equipment operates without any worries throughout the process. It is an industrial production equipment with extremely high cost performance. Many customers have expressed that the factory layout planning and raw material supply and other supporting services provided by the manufacturer have further simplified the production start-up process, truly achieving "one-stop implementation", making it a reliable supplier worth long-term cooperation.

FAQ

To ensure that we recommend the most suitable equipment model for your production needs and reduce communication costs, please provide the following core information. Thank you for your support!

1.weight for plastic product

2.pictures for plastic product (including dimension for plastic product)

3.what output per hour do you need ?

4.Other requirements about the machine you want.

By the way , Our company is located in the vicinity of Shanghai, with a driving time of only about one hour. We welcome customers from all walks of life to make an appointment for factory visits at any time. We will provide you with professional on-site explanations and demonstrations!